Everyday 3D-Printing Examples

A few months ago, a few colleagues chipped in on a bambu carbon x1 printer. There are several benefits of sharing a 3D-printer as the types of skill, interest, materials and so forth differs. We quickly got a thriving where caffeine was replaced (or rather combined) by PLA/PETC/PA.

I can clearly see a few months later the emergence of these 3D printed objects around the house. These objects are often fetched from the internet through sites like printables.com, thingiverse.com ++. More than often these files needs some modification or are just hacked to serve some other purpose. Regardless, the access to fully customized and cheap solutions are impressive and I would like to dedicate a few minutes to give some examples!

Example 1 – Tool holders

I love to have access to my tools. Ofcourse I found some very nice templates on printables: https://www.printables.com/model/437327-universal-cordless-drill-holdermount-makita-dewalt

While this design can be improved to review strength and access to screws it has worked flawlessly with minimal effort!

Example 2 – Gopro Garmin Mount

I had a need to mount my cycling light to a gopro chest-strap. This would allow me 1500 lumens on my nightly nordic-ski adventures. Just acquiring a piece with these proprietary mounts would be nearly impossible (I’ve tried) or very expensive. Instead I was able to merge a few designs and print it to only find out I had the male go-pro mount which as was nothing a regular saw couldn’t fix. Well lit trip was enjoyed short there after!

Example 3 – Toys!

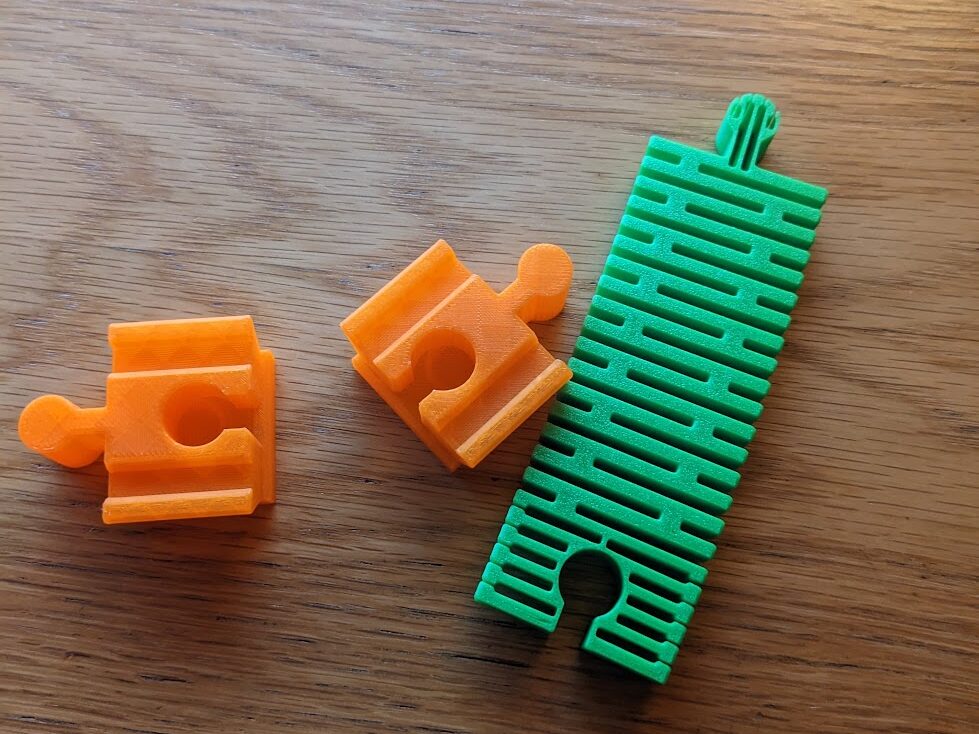

This is the big one. Regardless of any need that might pop up, nothing is as fun as sharing time with the kids. Having a 3D printer really opens up for more exquisite brio/duplo train-tracks. Being able to create converters and new joints is extremely fun. The converters had to be modified slightly and are now regularly mass produced at the office.

These opens up for many level train-tracks

Ending thoughts

In the end 3D printing is quickly becoming the go-to solution where novel and customized solutions are required. With access to fantastic starting points and an increasing knowledge of printing and materials it gets easier and easier to go from thought to working product!